Latest Blog Posts

Stay updated with industry trends, expert tips, and company news from Asian Bond.

The Ultimate Benefits of Using Concrete Floor Hardeners

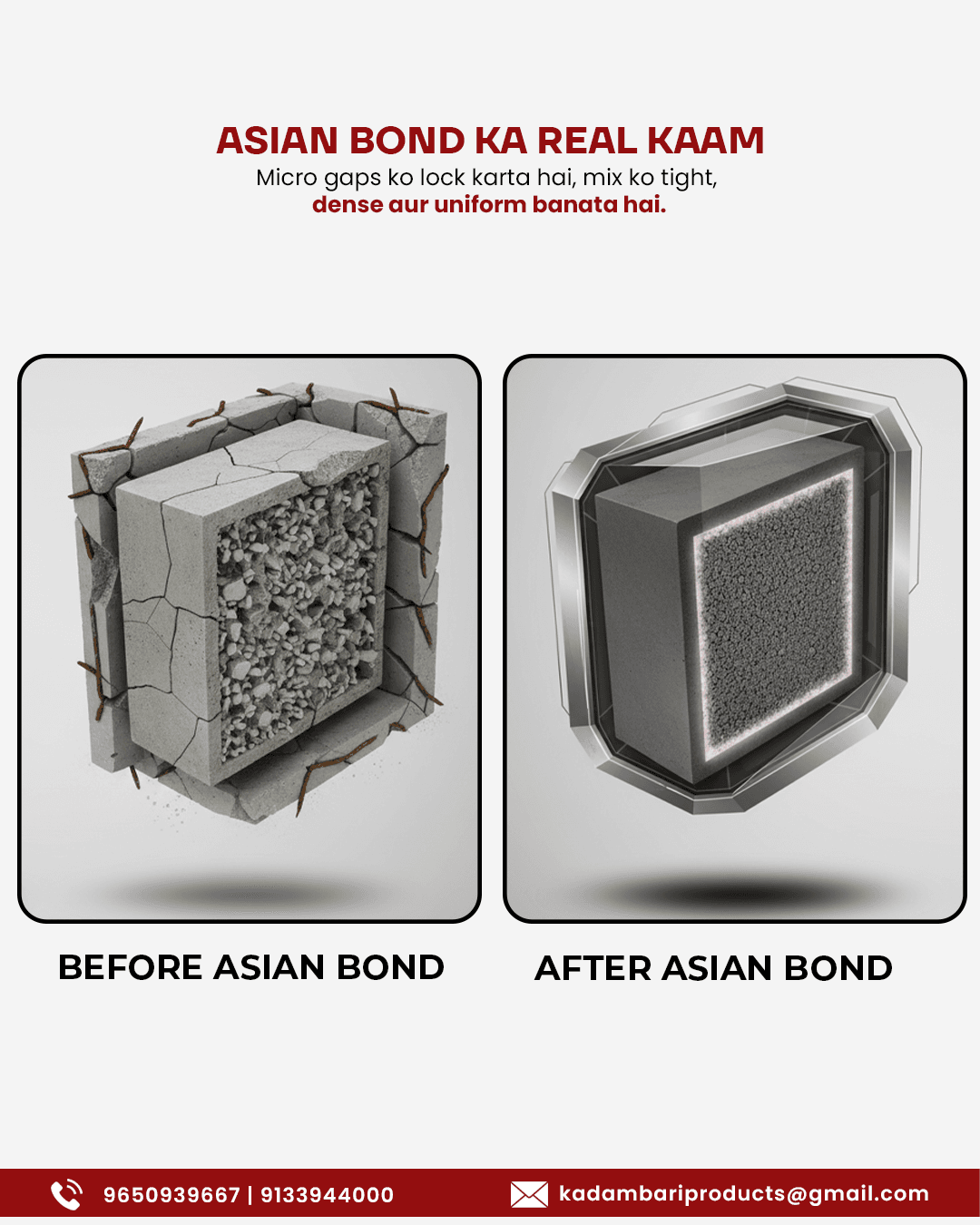

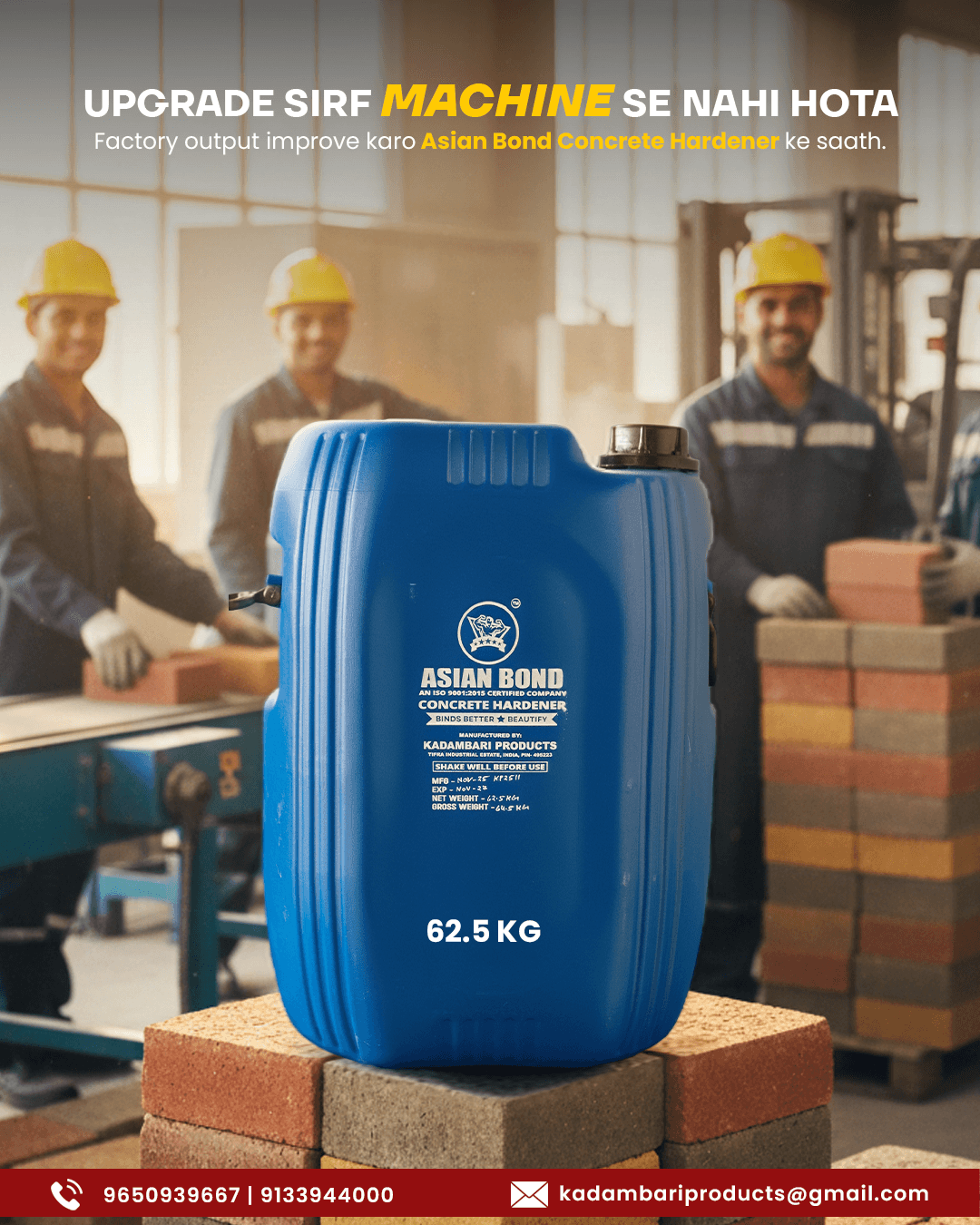

Concrete hardener is a specialized chemical solution used to significantly improve the strength, durability, and lifespan of concrete surfaces, especially in environments demanding high abrasion resistance and longevity. The right choice of concrete hardener can boost project efficiency, ensure structural integrity, and provide lasting value Asian Bond is a leading name in this segment, recognized for its advanced formulations in India.

Understanding the Difference Between Concrete and Cement Hardeners: A Comprehensive Guide

In the modern construction industry, achieving superior concrete performance requires more than just traditional mixing techniques. Chemical hardener for concrete and cement hardener solutions have revolutionized how we approach concrete durability, strength, and longevity. Understanding the distinction between these hardening systems is crucial for construction professionals, manufacturers, and anyone involved in concrete applications.

The Complete Guide to Concrete Hardener: Revolutionizing Construction in India

In the changing construction landscape of India, the demand for concrete surfaces that are durable and high-performing has increased tremendously. From industrial warehouses to residential walkways, the need for concrete to remain strong and long-lasting has driven the enhanced use of concrete hardener technology. This guide, inspired by industry insights, explains how concrete hardeners can be a game-changer—highlighting the innovative products offered by Asianbond and their adaptability across diverse construction applications.

Step-by-Step Guide to Paver Block Hardener for Maximum Performance

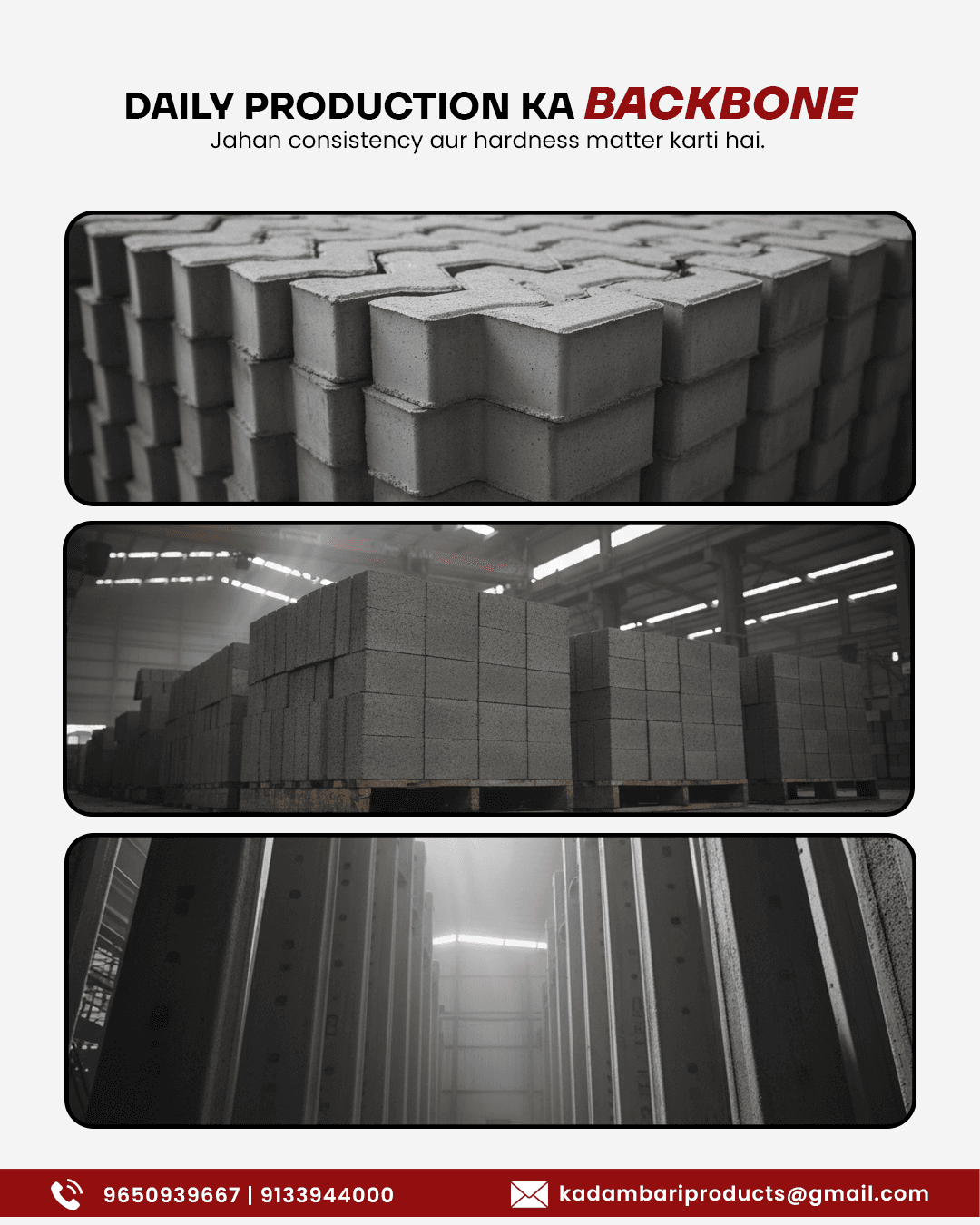

Paver blocks are widely used in driveways, walkways, patios, and public spaces due to their durability, strength, and aesthetic appeal. Their full potential can only be realized not just by using quality raw materials but also by incorporating concrete hardeners in the production process.

Common Mistakes in Using Concrete Chemicals: A Professional Guide with Insights on Concrete Hardeners

Concrete chemicals are game-changers in modern construction—improving longevity, functionality, and even aesthetics of structures. However, their misuse can lead to poor performance, structural issues, and wasted investment.

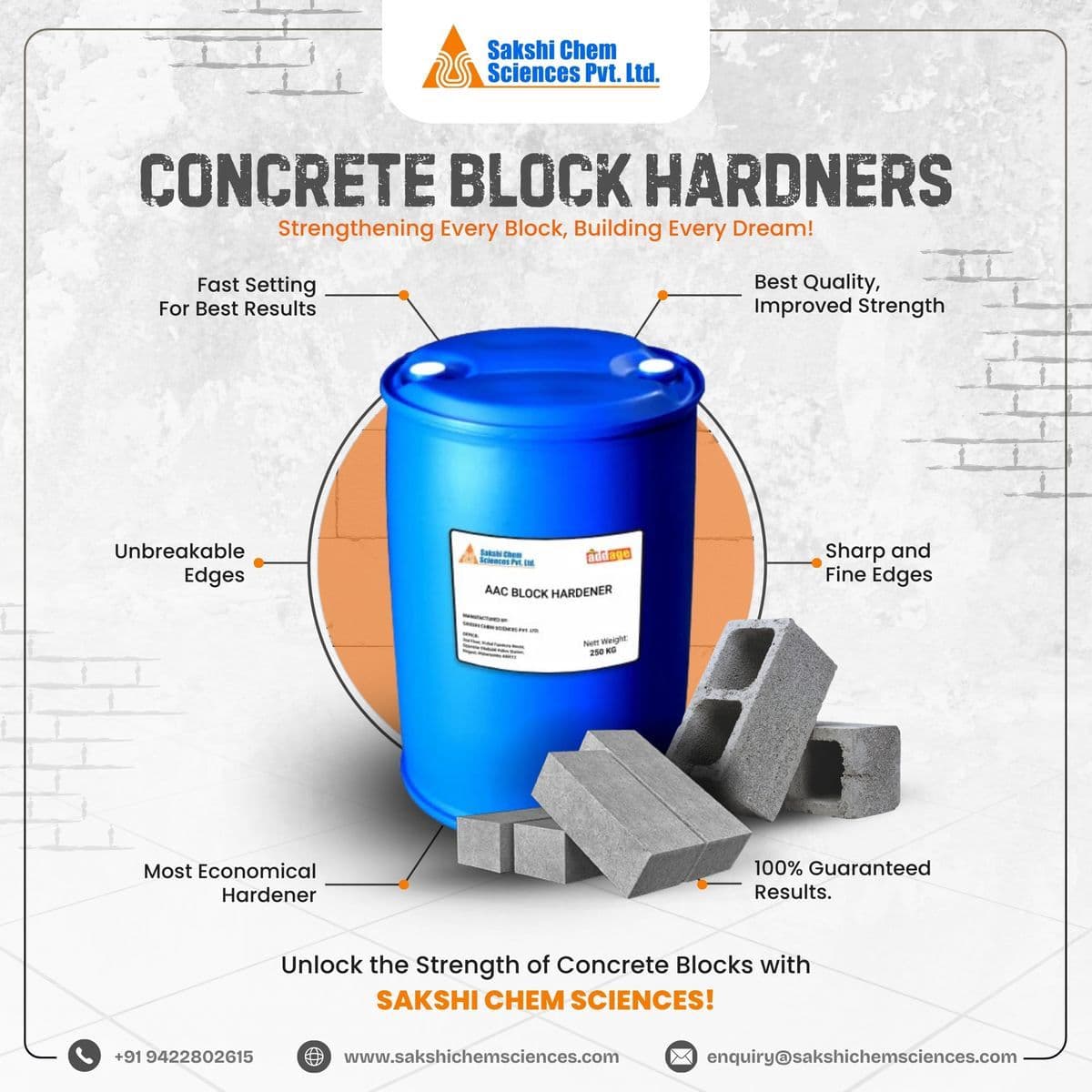

Increasing Block Strength: Strategies, Innovations, and the Role of Asian Bond Concrete Hardeners

The strength of concrete blocks is fundamental to ensuring durability, safety, and longevity in all construction projects. From residential homes to commercial complexes and large-scale infrastructure, strong blocks form the backbone of robust architecture.

How Does Weather Affect Ready Mix Concrete and Tips to Reduce Risk

Hot weather accelerates hydration, causing rapid setting , plastic shrinkage, cracks, and reduced workability.Excessive temperatures also increase evaporation, resulting in inadequate curing and weaker long-term strength.

How Asian Bond’s Construction Chemicals Improve Construction Efficiency

The construction industry is evolving rapidly with growing demand forfaster execution, durability, and cost-effective solutions. Traditional methods often fail to meet modern expectations of strength, aesthetics, and sustainability.

The Future of Construction Chemicals in India: Trends for 2025

The Indian construction industry is undergoing a massive transformation, driven by rapid urbanization, mega infrastructure projects, and the rising demand for durable, high-performance building materials.

Concrete Hardener Manufacturer in India: A Complete Guide with AsianBond

India’s construction sector is rapidly evolving, with modern building techniques, smart materials, and high-performance chemicals driving new benchmarks for durability, aesthetics, and efficiency.

Concrete Hardener Supplier: How to Pick the Right One (AsianBond Focus)

Durable flooring is the cornerstone of modern construction—yet the difference between a robust industrial surface and one that fails under pressure often comes down to choosing the right concrete hardener supplier.

Asianbond: The Most Reliable Floor Hardener Supplier in India

When it comes to construction excellence, flooring solutions play a crucial role in defining durability, strength, and sustainability. From residential buildings to industrial setups and commercial complexes, the foundation of quality infrastructure depends on the right flooring materials.

Asianbond: The Most Reliable Floor Hardener Supplier in India

When searching for the best concrete hardener in India, contractors and builders increasingl turn to Asianbond — an industry leader renowned for reliability, quality, and innovation in construction chemicals.

Waterproofing Compounds and Sealants: Asianbond’s Advanced Solutions for Long-Lasting Structures

Asianbond has earned a stellar reputation for manufacturing and supplying high-quality construction chemicals that enhance the strength, durability, and performance of concrete structures.

How Concrete Admixtures Can Help You Maintain Strong, Crack Free Walls and Floors

Crack free and durable construction is every builder’s dream. Whether it’s floors, walls, or industrial surfaces, a structure’s long term strength depends on how well the concrete is formulated, mixed, and cured. In recent years, concrete admixtures have transformed this process by improving concrete’s workability, reducing shrinkage, and enhancing overall durability.

Concrete Hardeners: Myths and Misconceptions

Concrete hardeners are essential in the construction industry for enhancing the durability and strength of concrete surfaces. Their role becomes even more significant in industrial floors, paver blocks, and other high-traffic or exposed areas.

Cement Concrete Hardeners at Best Price in India: The Ultimate Guide for Builders and Contractors

Cement concrete hardeners are key chemicals that boost concrete’s strength, lifespan, and surface resistance. As construction projects surge across India, picking a top-performing hardener matters more now—for lasting results and savings.

Concrete Hardener H35 - HG Hyper Grinder: Revolutionizing Concrete Durability with Asianbond

Asianbond's Concrete Hardener H35 – HG Hyper Grinder is recognized as one of the best concrete hardeners in India, engineered to deliver superior strength and long-lasting performance across industrial, commercial, and precast applications.

Factors That Affect Concrete Hardener Performance

For strong, durable, and dust-free concrete surfaces, hardeners play a critical role in modern construction and flooring applications. Whether you are installing paving blocks, reinforcing warehouse slabs, or protecting brickwork, selecting a high-quality concrete hardener in India significantly improves performance while reducing long-term costs

Concrete Hardener – The Best Choice for Warehouse Flooring

In factory and warehouse environments, floor performance is non-negotiable. Heavy machinery, forklifts, pallet traffic, and continuous footfall place extreme stress on concrete surfaces. Without proper treatment, floors begin to chip, flake, or dust—creating safety risks and ongoing maintenance costs. This is exactly where concrete hardeners deliver long-term value.

Concrete Hardener — Benefits for Heavy Load Areas

In construction environments where floors face relentless pressure—warehouses, factories, loading docks—durability is non-negotiable. Heavy machinery, repeated traffic, and concentrated loads quickly expose the weaknesses of untreated concrete. This is where a concrete hardener proves its value, transforming ordinary slabs into dense, wear-resistant surfaces built to last.

Concrete Hardener Compatibility with Polishing Systems

Concrete that delivers both durability and a refined polished finish is no longer a luxury—it is a standard expectation in modern construction. Builders today demand strength, sheen, and longevity without compromising performance.

Concrete Hardener Explained Simply: What Is It Today?

Concrete today becomes significantly tougher through the use of advanced concrete hardeners. These are not simple sealants applied on top; they are reactive chemical agents that work deep inside the slab. By bonding with excess lime and filling microscopic voids, they gradually create a denser internal structure.

Concrete Hardener for Cold Climate Construction

Cold weather changes how concrete behaves. When temperatures drop, hydration slows, early strength suffers, and surfaces become vulnerable to cracking, dusting, and long-term failure. In such conditions, standard concrete mixes often fall short.

Concrete Hardener for Home Floors – Worth It or Not?

A stronger floor today often means fewer repairs tomorrow. Across India, homeowners and builders are increasingly choosing concrete hardeners to extend the life of residential floors. These treatments are no longer limited to factories or warehouses. Brands such as AsianBond have brought professional-grade concrete hardening solutions into homes—enhancing durability without compromising appearance.

Concrete Hardener for Long-Term Cost Savings

Concrete is strong, but years of stress, moisture, and chemical exposure slowly wear it down. Applying a concrete hardener strengthens the surface, extending the life of slabs, walls, and floors. This directly reduces repair frequency and long-term maintenance costs. Builders seeking durable outcomes across factories, offices, and homes often rely on AsianBond’s concrete hardener for this reason.

Environmental Benefits of Modern Concrete Hardeners

What sets modern concrete hardeners apart is not only durability, but how effectively they reduce environmental strain. Longer-lasting concrete means fewer repairs, fewer replacements, and less construction waste over time. Selecting a reliable solution such as AsianBond helps projects avoid repeated rebuilds, lowering fuel use, material consumption, and emissions linked to transport and maintenance.

Concrete Hardener Guidelines for Construction Workers

Working with concrete means dealing with wear every single day. Warehouse floors absorb constant impact from machinery, walkways erode under steady foot traffic, and untreated slabs slowly turn dusty and weak. A reliable solution becomes essential once surfaces start breaking down. Modern concrete hardeners—especially trusted formulations produced in India by companies such as Asianbond—penetrate beneath the surface and reinforce concrete where it matters most.

How Long Does Concrete Hardener Take to Cure?

A structure stays reliable only when its foundation performs as intended. Concrete supports homes, offices, factories, and infrastructure, yet even this durable material can lose surface strength over time. Abrasion, chemicals, and moisture slowly weaken untreated slabs. To prevent this, builders often apply a concrete hardener after pouring. This treatment improves durability from within, extending floor life while reducing chipping, dusting, and surface breakdown.

Concrete Hardener for Export Warehouses and SEZ Units

In export warehouses and Special Economic Zone (SEZ) units, floors operate under relentless stress. Forklifts move continuously, pallets stack high, machinery runs without pause, and downtime is costly. Weak concrete surfaces quickly crumble, peel, or dust—interrupting operations and inflating maintenance costs. This is where treated concrete becomes essential.

Concrete Hardener for Cold Storage and Temperature-Controlled Areas

In cold storage facilities and temperature-controlled environments, floor performance becomes mission-critical. Sub-zero temperatures, persistent moisture, forklift movement, and repeated thermal cycling place extreme stress on ordinary concrete. Without proper protection, surfaces crack, powder, and deteriorate rapidly.

Concrete Hardener Helps Concrete Floors Last Longer

Concrete floors take daily abuse where machines roll, loads drag, and foot traffic never stops. When left untreated, surfaces begin to crack, shed dust, and form rough patches that demand constant repair. A liquid concrete hardener changes that trajectory. By penetrating deep into the slab, it restructures the material from within, extending service life and reducing maintenance costs over time.

Grind N Shine Concrete Hardener by AsianBond

Floors begin to last noticeably longer when concrete is treated correctly. Factories report fewer cracks, paver blocks withstand harsh weather with ease, and brick surfaces gain a clean, durable finish where erosion once showed up early.

Concrete Hardener for Smart Cities and Urban Projects

Cities are expanding faster than ever, and the materials beneath them must endure constant stress. Busy streets, pedestrian walkways, transport hubs, and utility corridors face heat, rain, pollution, and heavy traffic every single day. Concrete hardener plays a critical role here—turning ordinary concrete into a long-lasting, high-performance surface built for modern urban demands.

Concrete Hardener for Warehouses

Warehouse floors face relentless stress. Forklifts roll nonstop, heavy pallets scrape across aisles, and fine dust rises as untreated concrete slowly breaks apart. Over time, edges chip, cracks widen, and surface powder spreads into equipment and work zones. Repairs arrive sooner than expected, disrupting operations and increasing safety risks. A high-performance concrete hardener changes this cycle by strengthening the slab from within. Across India, AsianBond provides this protection—transforming ordinary warehouse floors into durable, long-lasting work surfaces built for constant load.

Concrete Hardener for Food Grade Flooring

Concrete floors in food-grade environments take constant punishment. Heavy machinery rolls all day, liquids spill often, and aggressive cleaning never stops. Breweries, dairies, pharmaceutical plants, and food processing units demand floors that resist stains, prevent slipping, and block bacterial growth. Ordinary concrete struggles under these conditions. A concrete hardener changes that reality by strengthening slabs from within. Across India, Asianbond has emerged as a trusted name for food-safe concrete hardening solutions designed to last without compromising hygiene or safety.

Lithium Concrete Hardeners Replace Sodium Silicates by 2026

By 2026, a quiet but decisive shift has reshaped how concrete floors are strengthened. Where sodium silicate once dominated job sites, lithium-based concrete hardeners have taken the lead. Designers, engineers, and contractors now expect more than acceptable durability — they want long service life, minimal dust, and predictable performance under heavy loads. Older methods no longer meet those expectations. Lithium chemistry does.

2026: The Rise of Nano Hardening for Longer-Lasting Materials

By 2026, construction no longer revolves around pouring thick concrete and hoping it holds. Strength today is engineered at the smallest scale, reshaping materials from the inside out. Nano-hardening has emerged as the defining shift — not as a trend, but as a measurable upgrade in durability. Builders care less about labels and more about outcomes: less labor, fewer repairs, and materials that last twice as long. At the center of this change stands Asianbond, introducing advanced chemistry into India’s rapidly expanding infrastructure.

The Complete Reference on Concrete Hardeners for Basements and Underground Buildings

Below ground level, construction faces a very different reality. Basements, underground parking areas, and sub-structures remain in constant contact with moisture, soil pressure, and heavy loads from the structures above. In these spaces, strength is not optional—it is essential. Concrete that is not properly hardened begins to crack, dust, and weaken far sooner than expected. Long-term durability depends on what penetrates the concrete during construction, not just what covers it later. Protection must begin from within.

Concrete Hardener for Forklift, Pallet Truck Movement Areas: Strengthen Your Floors with AsianBond

In warehouses, factories, and distribution centers, concrete floors face relentless punishment from forklifts and pallet trucks. Continuous movement under heavy loads causes dusting, surface pitting, and cracking that disrupt operations and inflate maintenance costs. A high-performance concrete hardener changes this outcome by converting weak, porous slabs into dense, long-lasting industrial floors.

AsianBond Cement Hardener Maker Bilaspur

Across India’s industrial corridors and fast-growing construction zones, dependable building materials keep projects moving. From Bilaspur, AsianBond has built a reputation for manufacturing high-performance cement and concrete hardening chemicals designed to withstand sustained pressure. Their products strengthen plant floors, warehouses, and block paving systems used nationwide. For builders and contractors in Chhattisgarh searching for reliable suppliers, AsianBond frequently emerges as the first choice. Beyond state boundaries, the brand is equally trusted for consistent quality and dependable supply.

Concrete Hardener for Airport Hangars and Logistics Yards with AsianBond

Airports and freight hubs operate under some of the harshest conditions any concrete surface will ever face. Aircraft loads, nonstop truck traffic, sudden chemical spills, and extreme weather all combine to punish floors relentlessly. In such environments, surface coatings alone are not enough. What is required is a concrete hardener that strengthens from within. AsianBond delivers exactly that—transforming vulnerable slabs into dense, high-performance surfaces built to endure.

Concrete Hardener for Dust Control in Concrete Floors

Where concrete floors take daily punishment, strength is not just about load-bearing—it is about resisting breakdown under constant stress. In warehouses, factories, and even older homes, one persistent issue keeps returning: concrete dusting. That fine powder coating shelves and corners is more than a cleaning nuisance; it signals surface degradation from within.

AsianBond Concrete Hardener Used in Food Processing

In food processing environments, floors face relentless stress. Heavy wheels roll through nonstop, liquids spill without warning, and machines push surfaces to their limits. Weak concrete fails quickly under these conditions. AsianBond concrete hardener is engineered for this exact reality—designed to strengthen floors from within so they resist breakdown year after year. This durability is not accidental; it is built through chemistry that permanently changes how concrete performs.

Concrete Hardener for Stadiums and Sports Complexes Built to Last with Asianbond

Stadiums and sports complexes push concrete far beyond normal limits. Beneath roaring crowds, sprinting athletes, and heavy event equipment, floors face constant abrasion, impact, and cleaning cycles. Standard concrete breaks down quickly under this pressure. Asianbond concrete hardener is engineered for exactly these conditions, strengthening concrete from within so surfaces stay intact for decades.

Asianbond 25 kg Cement Concrete Hardener Stands Out in India

Across India’s fast-growing construction landscape, durability decides success. From paver block driveways to factory floors carrying heavy machinery, choosing the right concrete hardener matters far more than many expect. Asianbond’s 25 kg cement concrete hardener is engineered to convert ordinary concrete into a dense, high-performance surface that withstands stress over time.

Concrete Hardener Makes Concrete Floors Last Longer

Concrete floors support the spaces where real work happens—warehouses, machine halls, parking areas, and even residential garages. Every day, heavy footsteps and rolling equipment punish the surface. Left untreated, concrete begins to crack, dust rises, and breakdown starts far sooner than expected.

How Today’s Concrete Hardeners Help the Environment

Modern concrete hardeners do more than strengthen floors — they quietly reduce environmental impact across the entire lifecycle of a structure. By extending service life, they reduce how often concrete must be repaired or replaced. Fewer rebuilds mean less raw material use, lower emissions, and reduced waste overall. Asianbond stands out in this shift, offering formulations engineered for durability with cleaner chemistry.

How to Apply Concrete Hardener Correctly for Long-Lasting Floors

A solid surface begins with smart choices. Using a concrete hardener makes floors tougher against wear, reduces dust, and increases strength under load. When applied correctly, it extends the life of industrial slabs, driveways, storage areas, masonry units, and precast elements. Across India, AsianBond is widely chosen because its formula performs reliably under heat, heavy traffic, and changing weather.

Concrete Hardener for Sustainable Construction

What once seemed optional now feels necessary. As construction shifts toward smarter, longer-lasting methods, material choices matter more than ever. Concrete hardeners quietly play a critical role here—strengthening floors from within, reducing waste, and helping structures last decades longer. The impact isn’t loud, but it’s lasting.

Concrete Hardener Use in Ready Mix Floors

Ready-mix concrete floors dominate modern construction across warehouses, factories, parking zones, and retail spaces. Their appeal lies in speed, consistency, and smooth finishes delivered straight from the truck. Yet over time, even well-poured RMC floors face wear from foot traffic, rolling machinery, and environmental stress. This is where concrete hardeners quietly step in—locking loose particles, stopping dust, and improving resistance where it matters most.

Can Old Concrete Floors Be Treated with Hardener? A Complete Professional Guide

Old concrete floors often show their age through cracks, dusting, surface softness, and loss of grip. Factories, warehouses, parking areas, homes, and retail spaces all face this issue over time. Many assume demolition is the only fix, yet modern construction practices offer a smarter alternative—strengthening the existing slab with a concrete hardener.

Concrete Floors Weaken Without Hardening

Concrete floors support factories, storage spaces, homes, and shared areas across India. While concrete appears strong, its long-term performance depends heavily on proper hardening. When left untreated, slabs begin to chip, crumble, and wear far earlier than expected. A liquid concrete hardener prevents this decline by strengthening the surface from within.

Concrete Hardener for Old Concrete Floors: Does It Work?

A properly applied concrete hardener can bring aged concrete floors back to life. Older slabs that have lost strength, started dusting, or softened under traffic often respond well when treated correctly. Products such as Asianbond penetrate deep into worn concrete, reinforcing weak zones instead of merely masking surface damage. Age alone does not disqualify a floor—condition and preparation matter far more.

Concrete Hardener for High-Traffic Commercial Areas

Commercial environments such as retail stores, warehouses, factories, garages, markets, transport hubs, and production facilities face nonstop stress every day. Constant foot traffic, rolling loads, vibration, and impact slowly wear down untreated concrete. Even strong slabs weaken when friction and shock repeat without protection. That is why long-term surface defense becomes critical. A concrete hardener reinforces vulnerable zones, transforming weak surfaces into resilient working floors built for endurance.

How Concrete Hardener Improves Abrasion Resistance

Modern construction demands surfaces that withstand constant use. Walkways, factory floors, warehouses, and parking zones endure daily scraping, rolling loads, and repeated impact. Over time, untreated concrete gradually weakens. Surface particles loosen, micro-cracks develop, and abrasion slowly erodes the top layer.

Concrete Hardener Guide for Parking and Basement Floors

Basement levels and parking zones endure some of the heaviest stress within any structure. Vehicles move constantly, fluids leak, moisture penetrates, and repeated weight loads press into the slab. Without protection, concrete begins to powder, crack, and weaken over time.

Concrete Hardener Quality Testing & Standards

Concrete hardeners significantly influence how long floors and slabs perform under stress. Proper quality testing ensures builders, contractors, and developers can rely on measurable performance rather than marketing claims.

Asian Bond Concrete Hardener Compared to Others

In modern construction, material performance determines long-term structural value. Selecting the right concrete hardener directly impacts durability, maintenance cost, and lifecycle performance. With numerous suppliers across India, distinguishing between marketing claims and measurable results becomes critical.

Benefits of Concrete Floor Hardeners

Concrete surfaces in warehouses, factories, retail stores, and homes endure constant mechanical stress. Forklifts grind across slabs, foot traffic accumulates daily wear, and spills slowly degrade untreated concrete. Without reinforcement, surface dusting, abrasion, and micro-cracking accelerate deterioration.

Concrete Hardener – Surface Treatment Guide

Concrete forms the backbone of modern construction. From warehouses and factories to parking areas and residential driveways, concrete floors carry heavy loads and constant movement every day. Over time, untreated surfaces begin to weaken — dust forms, micro-cracks develop, and abrasion reduces structural integrity.

Concrete Hardener – Durable, Efficient, and Versatile

Strength is fundamental in modern construction. Industrial floors, warehouses, retail spaces, parking areas, and residential slabs all require resistance to abrasion, impact, and environmental stress. Without reinforcement, concrete gradually deteriorates under load and traffic.

Concrete Hardener Suppliers: Compare Features & Get the Best Deals

Durable flooring begins long before the final finish. Concrete must be strengthened properly to withstand heavy machinery, storage loads, constant vehicle movement, and environmental exposure. Choosing the right concrete hardener supplier determines whether a floor lasts decades — or fails within years.

Floor Hardener Enhances Concrete Longevity

Concrete surfaces are everywhere — industrial plants, warehouses, parking areas, malls, airports, and even residential spaces. Over time, untreated slabs can crack, produce dust, and deteriorate under heavy loads. Applying a floor hardener transforms standard concrete into a tougher, more durable surface built to withstand long-term stress.

High Strength Concrete Hardener Chemical – A Guide to Durable Concrete

Concrete forms the backbone of infrastructure — from roads and factories to homes and commercial complexes. Its long-term performance depends on internal strength, not just surface appearance. High strength concrete hardener chemicals enhance durability by triggering reactions within the slab that increase density and reduce wear.

Concrete Hardener versus Concrete Sealer – Understanding the Contrast

Durability defines the success of any structure. Whether it is factory flooring, entry paths, warehouses, paver units, or shopping complexes, protecting the concrete surface is essential. Two common solutions are concrete hardeners and concrete sealers. While they may appear similar, their functions differ significantly in performance and long-term impact.

Where to Buy Concrete Hardener in Bulk at Best Price

In today’s competitive construction and infrastructure market, selecting the right concrete hardener is not just about increasing surface strength. It directly affects durability, lifecycle cost, and long-term structural performance. Whether managing industrial flooring or residential development, choosing the best concrete hardener in India significantly influences overall build quality.

Road Construction and the Use of Concrete Hardener

Road construction is one of the most demanding segments in civil engineering. Pavements endure continuous heavy vehicle loads, temperature fluctuations, rainfall exposure, and environmental stress. Durability is not determined by thickness alone — internal material enhancement plays a critical role. Concrete hardener solutions are increasingly used to extend service life and reduce premature deterioration.

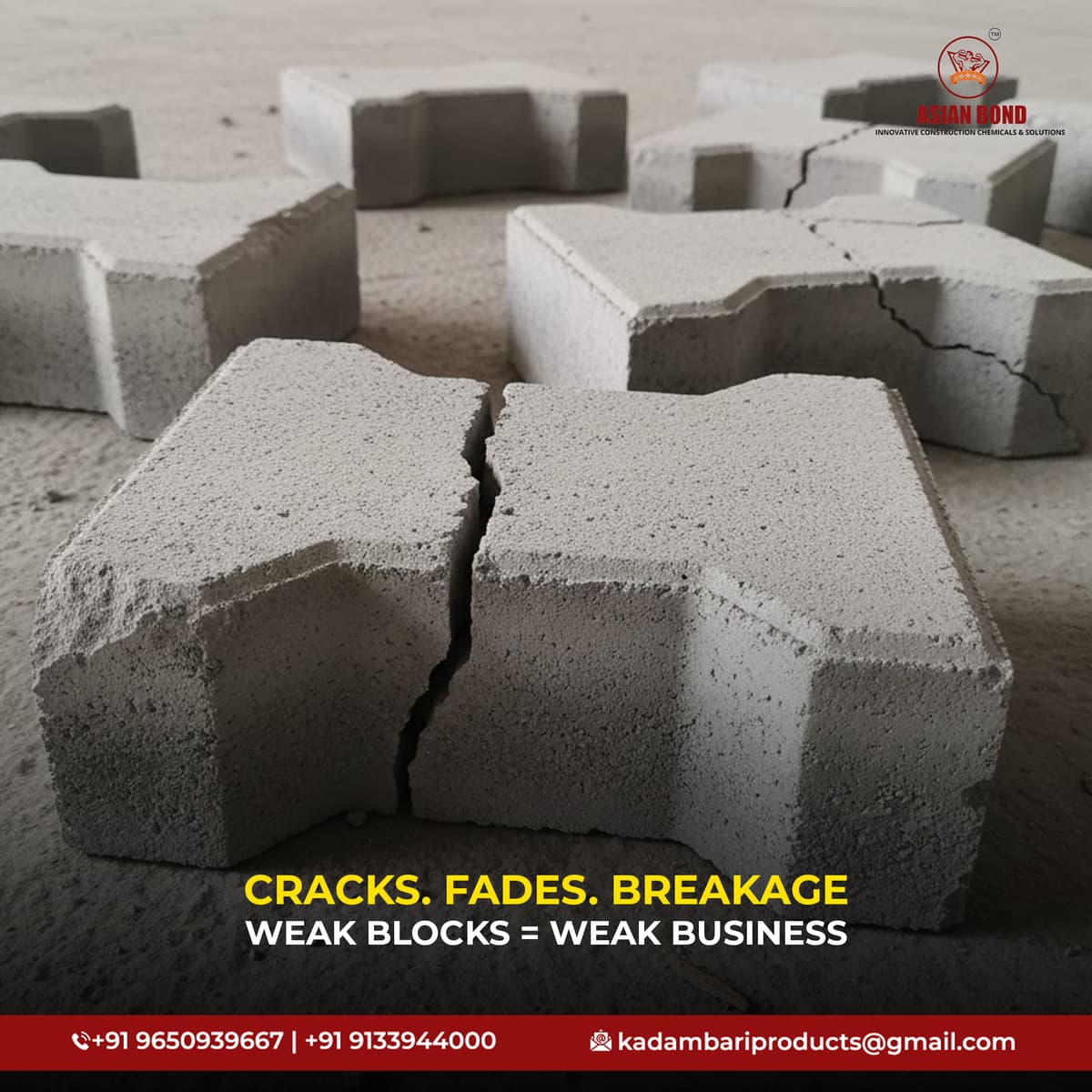

Repairing Weak Concrete with Chemical Hardeners

Even well-constructed concrete surfaces deteriorate over time due to continuous load exposure, environmental stress, and operational wear. Cracking, dusting, premature abrasion, and surface weakening commonly occur in factories, parking areas, warehouses, walkways, and brick structures. When concrete loses strength, it not only reduces structural efficiency but also increases maintenance costs and safety risks.