Floor Hardener Chemicals for Factory Floors: Best Options for Heavy-Duty Use

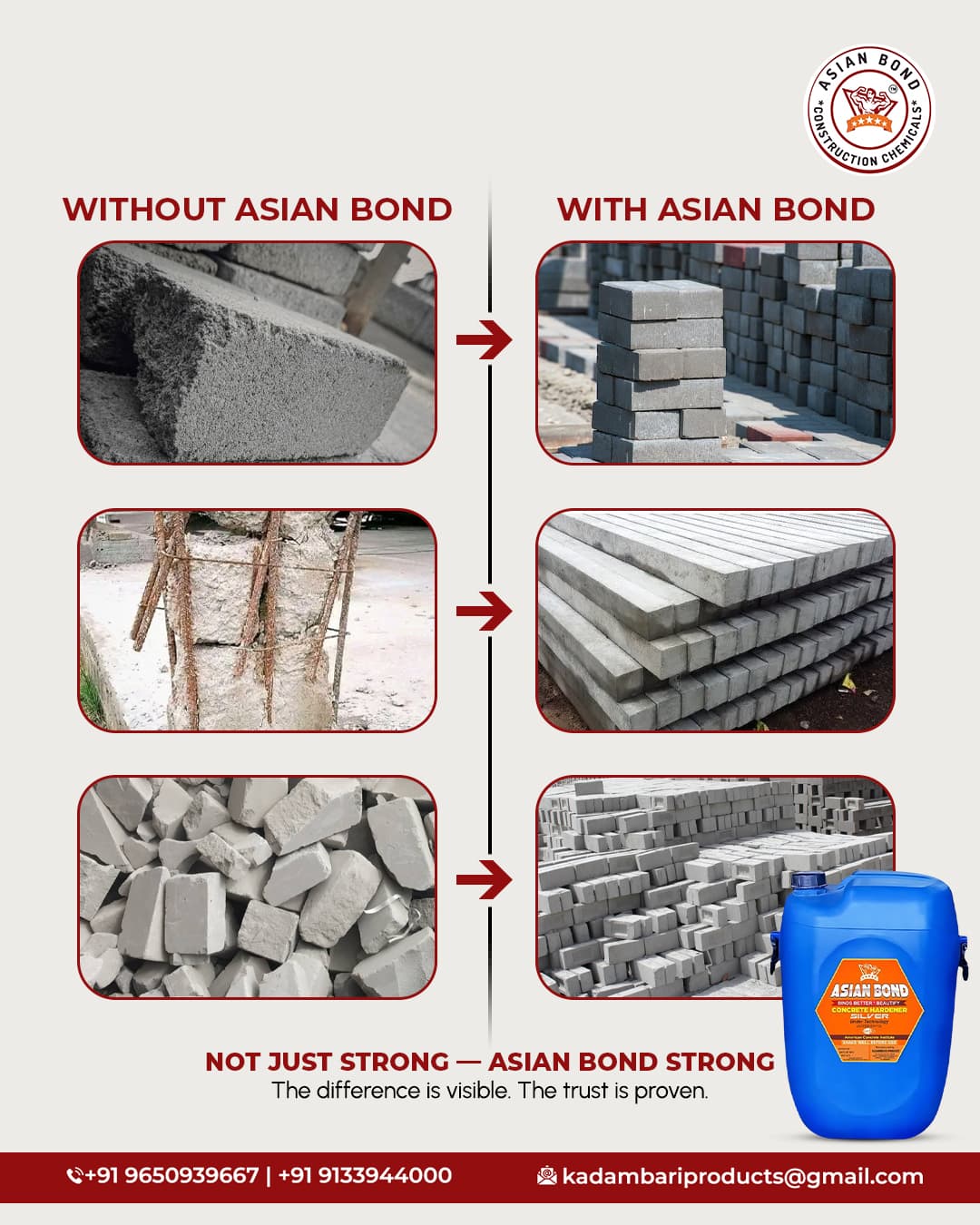

Floor hardeners turn basic concrete into tough, long-lasting surfaces—perfect for factories handling heavy machinery, nonstop movement, and chemical spills. For demanding environments, Indian brands like Asianbond stand out because their hardeners penetrate deeply and provide superior wear resistance.

Asianbond remains a trusted name among concrete admixture manufacturers in India, offering factory-grade floor hardener chemicals built for durability, strength, and zero dust environments.

What Is Concrete Hardener?

A concrete hardener is a liquid that reacts with free lime inside concrete to form strong, dense crystal structures. This reaction improves surface strength, reduces porosity, and increases durability—exactly what factories need. Unlike basic sealers, Asianbond’s premium formulas penetrate deep into the slab, reducing holes, cracks, and weaknesses over time.

Their factory floor hardener withstands forklift traffic, oil spills, impact loads, and industrial wear. Whether applied on new or old concrete, Asianbond products perform consistently well.

Why Factory Floors Need Heavy-Duty Hardeners

Factory floors endure constant stress—heavy loads, vibration, friction, and chemical exposure. Weak untreated concrete quickly dusts, cracks, and breaks down. Asianbond counteracts this with industrial-grade hardeners that can triple surface hardness while resisting spills and abrasion.

These benefits make Asianbond one of India’s top choices, especially when bulk pricing and local supply availability are important for large factory projects.

Types of Floor Hardener Chemicals

- Non-Metallic Floor Hardeners: Quartz-based hardeners ideal for standard factory floors—dust-free, rust-proof, and abrasion-resistant.

- Metallic Hardeners: Steel-infused blends for extreme loads—best for warehouses, loading bays, and automotive workshops.

- Liquid Concrete Hardeners: Deep-penetrating silicate formulas that strengthen slabs, bricks, and paver blocks from within.

Asianbond offers all three types, making them a leading concrete additive manufacturer in India with solutions for every industrial environment.

Asianbond: Best Concrete Hardener in India

Asianbond leads India's market with high-performance, eco-friendly hardeners designed for factories, paver blocks, brickwork, and commercial sites. Their chemical formulations act as shields against oil, acids, abrasion, and daily wear.

With widespread distribution, they ensure quick delivery and competitive wholesale rates nationwide.

Benefits of Asianbond Floor Hardeners for Factories

- Superior abrasion resistance for forklifts, pallet trolleys, and machinery.

- Strong defense against oils, greases, and factory-grade chemicals.

- Eliminates dust formation for cleaner, safer environments.

- Bulk discounts available—ideal for large industrial sites.

- Faster curing to reduce downtime and speed up project completion.

Applications Beyond Factories

- Paver Blocks: Prevents corner damage, cracking, and weather wear.

- Warehouses & Ramps: Handles high traffic and heavy loading.

- Brick Surfaces: Reduces efflorescence and improves density.

- Residential & Commercial Floors: Enhances durability and reduces maintenance.

How Chemical Hardeners Work

Asianbond hardeners use silicates—like sodium, potassium, or lithium—to react with calcium hydroxide inside concrete, forming additional C–S–H gel. This gel fills pores, prevents water penetration, and enhances resistance to wear and chemicals.

Whether applied as powder or liquid, Asianbond formulations bond deeply, making them ideal for industrial warehouses and high-load zones.

Application Guide for Heavy-Duty Floors

- Surface Preparation: Clean, remove dust, oil, or loose particles; ensure dryness.

- Apply Hardener: Spread dry shake over fresh concrete or spray liquid evenly.

- Trowel Finish: Work the material into the slab for proper bonding.

- Curing: Keep surface moist for 3–7 days for best results.

- Paver Mix Integration: Add hardener directly to the mix for stronger blocks.

Concrete Surface Hardener Price & Buying Tips

Prices vary depending on type (metallic, non-metallic, liquid) and quantity. Asianbond offers cost-effective rates—especially for bulk orders—with transparent pricing across 25–40 kg bags and liquid containers.

Comparison: Asianbond vs Competitors

| Feature | Asianbond | Competitors |

|---|---|---|

| Penetration Depth | Deep chemical reaction | Surface-level bonding |

| Factory Suitability | Heavy-duty optimized | General-use formulas |

| Bulk Pricing | Highly competitive | Higher per-unit cost |

| Paver Block Performance | Excellent | Moderate |

Why Choose Asianbond Over Others

Asianbond delivers tailored solutions, wide availability, proven results, and eco-safe formulas. Their products harden concrete faster, improve paver block production rates, and resist color fading—giving contractors long-term reliability.

Maintenance & Longevity

Floors treated with Asianbond require minimal maintenance—regular cleaning helps them last years. Avoid harsh scrubbing to preserve the hardened layer. With periodic checks, Asianbond-treated floors offer long-term stability.

Buy Concrete Hardener in Bulk from Asianbond

If you're ready to upgrade factory flooring, paver production, or industrial sites, Asianbond offers bulk-ready solutions with competitive pricing and strong support. As one of India’s leading concrete hardener manufacturers, they provide reliable, high-strength options for every scale of construction.