Concrete Hardener Chemical – Superplasticizer for Concrete: A Complete Guide to Strengthening Your Construction Projects

Modern construction demands materials that deliver exceptional strength, durability, and longevity. Among the most crucial components in achieving superior concrete performance are concrete hardener chemicals and superplasticizers. These advanced admixtures have transformed construction standards across India, offering enhanced workability, long-term durability, and climate-ready solutions tailor-made for challenging conditions.

Understanding Concrete Hardener: The Foundation of Durable Surfaces

A concrete hardener is a specialized chemical compound designed to increase the strength, density, and abrasion resistance of concrete surfaces. When applied correctly, a chemical hardener for concrete penetrates deep into the substrate, reacting with calcium hydroxide compounds to create a denser, more durable surface capable of withstanding heavy loads, chemical exposure, and environmental stress.

The best concrete hardener in India is engineered to perform across India’s diverse climatic zones. Brands like Asianbond, Sika, and Fosroc offer both dry-shake and liquid formulations developed for industrial, commercial, and residential applications.

How Concrete Hardeners Work

Concrete hardeners function through a chemical reaction with free lime within the concrete. Formulas rich in reactive silica—such as silicates and siliconates—penetrate the concrete surface, producing calcium silicate hydrate (C-S-H). This gel fills microscopic voids, creating a harder, denser, dust-free surface that resists abrasion, chemicals, and weathering.

Types of Concrete Hardeners Available in India

Liquid Concrete Hardener for Bricks

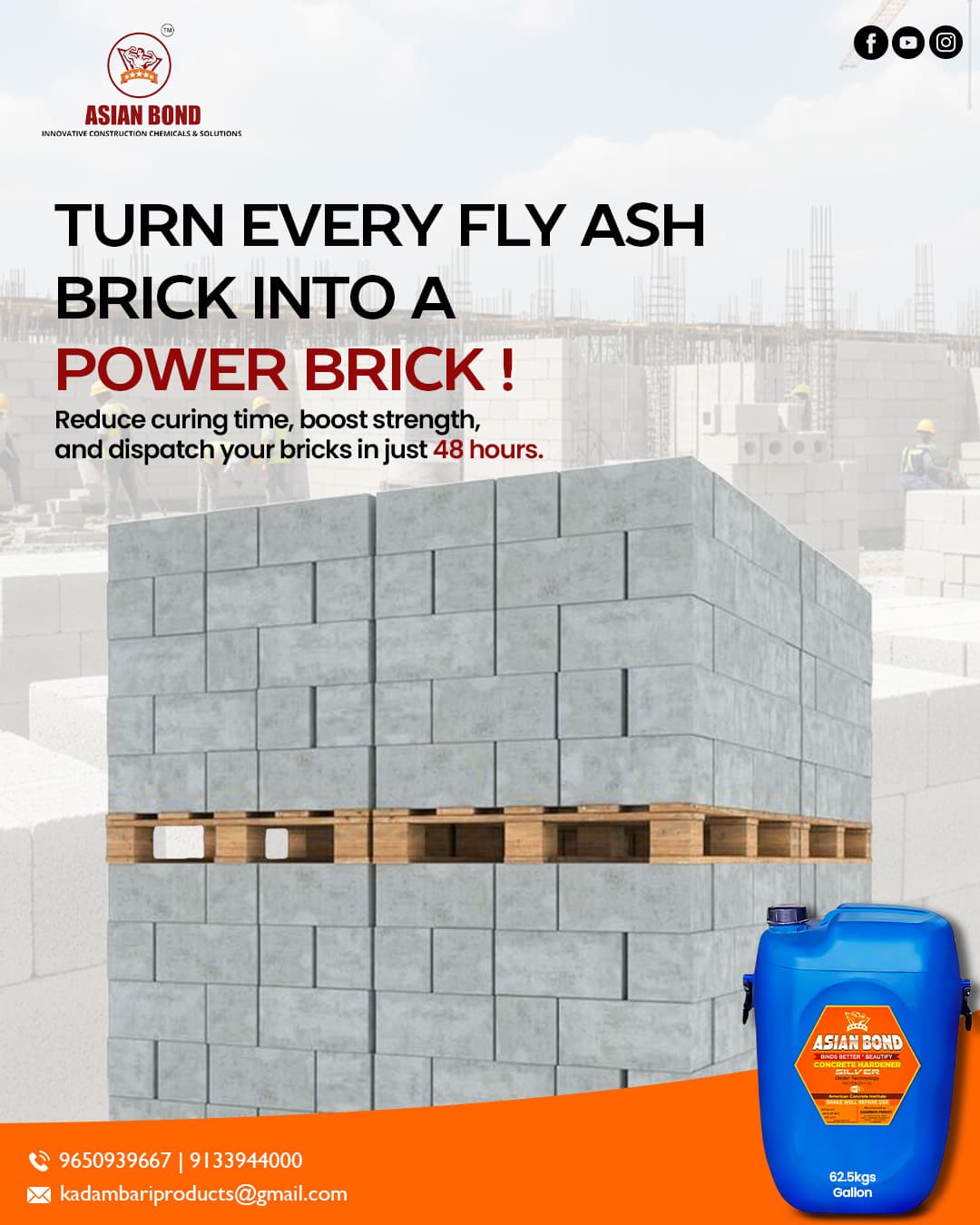

Liquid concrete hardeners containing sodium or lithium silicate offer deep penetration and rapid sealing, making them ideal for bricks, precast blocks, and dense concrete surfaces. These formulations accelerate strength gain and reduce porosity.

Concrete Hardener for Paver Blocks

A concrete hardener for paver blocks accelerates setting and curing, allowing early demolding and higher production rates. These hardeners also boost compressive strength and waterproofing—helping pavers withstand traffic, moisture, and harsh weather.

Floor Hardener Chemical for Factory Floors

Designed for industrial environments, a floor hardener chemical for factory use offers high abrasion resistance, impact durability, and protection against chemical spills. Ideal for heavy-duty floors exposed to machinery and vehicular movement.

Superplasticizers: High-Performance Water Reducers

While concrete hardeners improve cured concrete, superplasticizers optimize concrete while it’s still fresh. These high-range water reducers improve workability, reduce water content by 12%–30%, and significantly increase compressive strength by lowering porosity.

Types of Superplasticizers

- PCE (Polycarboxylate Ether): Advanced generation, high water reduction (up to 40%), excellent slump retention, eco-friendly.

- SNF (Sulfonated Naphthalene Formaldehyde): Cost-effective, widely used in ready-mix and precast concrete.

- SMF (Sulfonated Melamine Formaldehyde): High flowability without altering setting time—ideal for fast precast outputs.

Key Differences: Concrete Hardener vs. Superplasticizer

Concrete hardeners are surface treatments applied to cured concrete to improve hardness, abrasion resistance, and durability. Superplasticizers, on the other hand, are mix-stage admixtures added during batching to reduce water content and improve flowability.

In Simple Terms:

- Hardeners = Surface strength & protection (post-pour)

- Superplasticizers = Workability & internal strength (pre-pour)

Applications and Benefits

Industrial and Commercial Flooring

Concrete hardeners provide long-lasting protection in warehouses, factories, and retail spaces—resisting abrasion, dusting, and chemical spills.

Paver Block Manufacturing

Using concrete hardener for paver blocks ensures faster demolding, higher production volumes, and superior block strength and weather resistance.

Large Infrastructure Projects

Superplasticizers are essential in bridges, highways, dams, and skyscrapers where high-strength, low-porosity concrete is critical.

Concrete Admixture Manufacturers India: Leading Innovation

India’s construction growth has led to rapid innovation among concrete admixture manufacturers India. Companies like Asianbond, Fosroc, Sika, and Mcon Rasayan produce a wide range of admixtures—plasticizers, superplasticizers, waterproofers, curing agents, and surface hardeners—designed specifically for Indian environmental and site conditions. Their products meet global standards while remaining cost-effective for Indian projects.